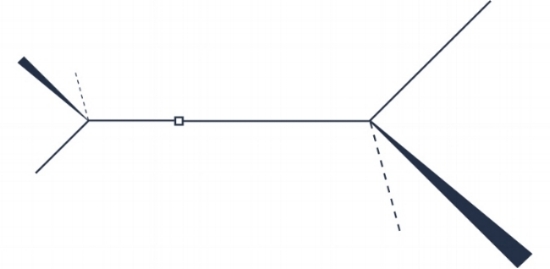

Experimenting multiple chassis designs for improved rigidity.

6 panels of 3/8" 4'x8' plywood boards were used to CNC cut 1:1 scale prototype.

Solidworks CAD modeling.

SLA parts ordered from Solid Concepts.

Initial part fitting test. Looks good!

Wheel and interior components were made with Z-corp process. Above: Zprint software interface.

Translucent parts are Accura 60 from Solid Concepts.

Part fitting test of internal components. Battery components dimensions were modeled after Prius plug-in conversion kits.

Accura 60 SLA parts were sanded up to 2000.

Accura 60 part transparency after lacquer clear coat application.

All parts were finished with Tamiya's lacquer spray paint. Pictured above: Tamiya Gunship Grey 2

Model making is an inter-disciplinary task. Last touch of graphic decals.

Pack and go mode.